Services

Testing and Maintenance Self Contained Breathing Apparatus

Maintain self-contained breathing apparatus in ready-to-use condition at all times: Our specialists perform an extensive cleaning & disinfection of your breathing apparatuses and a comprehensive testing using Quaester 7000 test equipment,from Dräger or other manufacturers – as needed or as part of a regular professional maintenance in your plant. Regional requirements as well as the manufacturer‘s specifications are taken into consideration and wear parts are replaced when necessary.

EEBD Testing and Maintenance

Maintain emergency escape breathing devices in ready-to-use condition at all times: Our specialists perform an extensive cleaning & disinfection of your EEBD and a comprehensive testing using Quaester 7000 test equipment, from Dräger or other manufacturers – as needed or as part of a regular professional maintenance in your plant. Regional requirements as well as the manufacturer‘s specifications are taken into consideration and wear parts are replaced when necessary.

Hydrotesting of Breathing Air Cylinders

Breathing air cylinders used in industry need to be hydrostatically tested every 3 or 5 years. These cylinders have a working life of 15 years or more from the date of manufacturing ,depending upon the material of construction. East wind safety have an accredited hydro static test station to conduct your cylinder testing. During a hydrostatic test, the cylinder is examined to ensure it can safely hold its rated pressure. SCBA cylinder hydrostatic testing is crucial as such containers can explode if they fail when containing compressed gas. A hydrostatic test consists of filling the cylinder with a nearly incompressible liquid—usually water—and examining it for leaks or permanent changes in shape. The test pressure is always considerably more than the operating pressure to give a margin for safety. Typically, 150% of the operating pressure is used.

Installation, maintenance, and training of Fixed & portable Fire Extinguishers

Various simulations can be placed on the Dräger fire pan whereby fires of solid and liquid materials as well as electronic devices can be simulated realistically. The participants decide which fire extinguisher is best suited for which mock-up. Spray patterns of powder, foam, CO2 and water can be simulated with the water and compressed air-operated manual fire extinguishers. To ensure an optimal training result, the discharge time can be adjusted in advance.

East wind safety also offers service and maintenance of fixed and portable fire extinguishing systems, including,

- Periodic inspection, testing, service and certification of portable fire extinguisher.

- Hydro testing and refilling of portable fire extinguisher.

- On board inspections, Testing and certification of fixed CO2 systems.

- On board inspections, Testing and certification of FM 200 systems.

- On board inspections, Testing and certification of Foam & dry powder systems

Installation, maintenance and training of Fixed fire & gas detection system

East wind safety is capable of build, supply & maintaining complete range of wired and wireless fire & gas systems. Our services include,

SITE ASSESSMENTS AND HAZARD IDENTIFICATION

SAFETY SYSTEM DESIGN AND OPTIMIZATION

SYSTEM INTEGRATION AND COMMUNICATION

PROJECT MANAGEMENT

SYSTEM VALIDATION AND FACTORY ACCEPTANCE TEST

STARTUP AND COMMISSIONING

TECHNICAL SUPPORT

ONGOING SERVICE AND MAINTENANCE

CUSTOMIZED TRAINING

Calibration & maintenance of fixed and portable gas detectors

A calibration of the gas detectors should be performed as per manufacturer recommendations, to compensate the sensor drift. East wind safety offers the calibration and maintenance services which ensures that your measurement devices are always perfectly calibrated. Our technicians perform professional and regular calibrations in accordance with your regulatory requirements.

Installation, maintenance and training of fire alarm systems

East wind safety provide a variety of Service and Maintenance packages for full-service contracts of your entire Fire alarm System

Our expert technicians will carry out inspections and repairs to ensure that you always have Peace of mind.

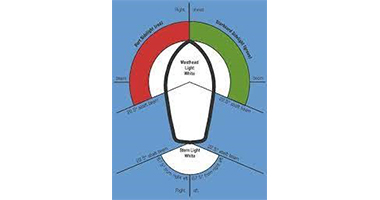

Installation, maintenance and testing of navigation light systems.

East wind safety offers a regular based service to prevent sudden system failures. one of our Service Engineers will check your system thoroughly. This way, the risk of failure will be minimal, and this therefore also reduces maintenance costs. By maintaining proper record of onboard service, any defects that are identified can be resolved quickly.

The main goal of our services is to provide overall safety and minimise the risk of sudden failures. This provides you with reassurance and, in the long term, peace of mind.

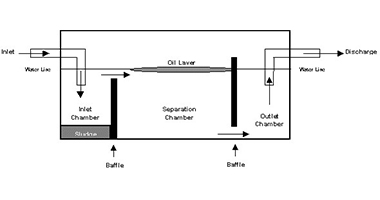

Installation, maintenance and calibration of oily water separator (OWS)systems.

East wind safety offers maintenance service for your oil water separator, it is possible to service the equipment in-house by following the manufacturers manual. Typical service intervals are between three and six months depending on the type of separator, the volume of water being processed and the amount of oil and sludge being removed.

Installation of bilge alarms system.

Installation of bilge alarms system.

Installation, maintenance and testing of engine and generator alarm monitoring system.

Installation, maintenance and testing of engine and generator alarm monitoring system.

Calibration of all pressure, temperature, linear, electrical and gas instruments.

Calibration of all pressure, temperature, linear, electrical and gas instruments.

Testing of level sensors, flow meters and various transmitters.

Testing of level sensors, flow meters and various transmitters.

Installation and repair of marine navigation and communication instruments.

Installation and repair of marine navigation and communication instruments.